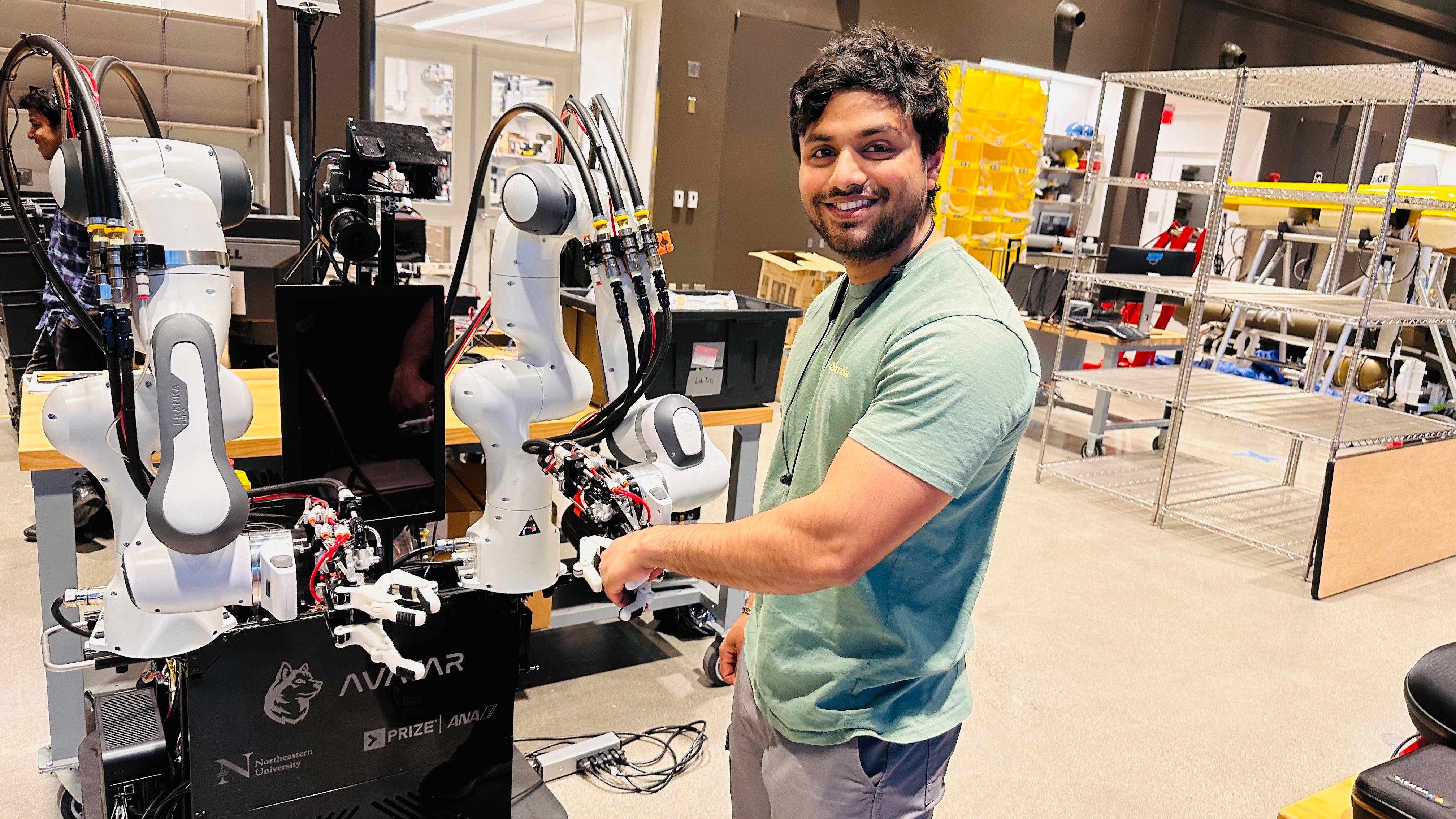

Welcome! I'mRuthvik

I Build Advanced Automation Systems

I'm a Mechanical & Robotics Engineer, passionate about designing automation solutions that enhance efficiency and precision. My goal is to create impactful systems in the robotics industry.

About Me

I'm Currently pursuing my Master's in Robotics, I'm passionate about creating innovative solutions in industrial automation and control systems. My expertise lies in hardware integration, PLC programming, and implementing robust control systems for automated processes.

Robotics & Automation

Designing and implementing automated systems and robotic solutions

PLC Programming

Developing reliable control logic for industrial applications

Control Systems

Implementing precise and efficient control mechanisms

Work Experience

With 4+ years of experience in industrial automation, I specialize in hardware integration, PLC programming, and robust control system design.

Titan Advanced Energy Solution

Robotics Engineer

- Designed 10+ custom fixtures achieving 95% defect detection accuracy and improved fixture reliability by 30%

- Led Beta 4 system deployment, achieving 900% throughput increase from 1.5 to 15 cells/min

- Integrated 140+ transducers and sensors for efficient one-pass cell scanning

- Programmed Siemens PLCs and implemented SCADA for real-time monitoring

Nutek Engineers

Mechanical Engineer

- Implemented Lean Manufacturing principles and Industry 4.0 techniques, reducing turbine blade manufacturing time by 20%

- Enhanced aero foil shape using Ultrasonic Testing, improving energy efficiency by 10%

- Utilized SolidWorks for design and implemented PID control system, reducing gate operation time by 70%

- Applied Statistical Process Control tools to optimize material handling systems

ABB Ltd

Automation Intern

- Contributed to innovative RFID scanning technology with spider-like agility

- Designed UHF RFID sensor integration system, improving data accuracy by 30%

- Developed precision actuators for dynamic environment adaptability

HAL

Manufacturing Intern

- Optimized manufacturability of Airbus A320 doors using advanced carbon-fiber composites

- Achieved 10% increase in material efficiency and 5% reduction in production time

- Generated cost savings of $22,000 while maintaining structural integrity

GCI Casting Pvt Ltd

Design and Manufacturing Intern

- Led precision casting of pallets and headers, reducing production time by 35%

- Achieved defect rates below 1% through ultrasonic and radiographic tests

- Employed Z-casting simulations and FEA, reducing material waste by 15% and saving $10,000/Quarter

Education

Northeastern University

Masters of Science Robotics

Minor: ECE & CE

Key Courses

DSATM

Bachelor of Engineering in Mechanical Engineering

Key Courses

CAD Portfolio

Explore my collection of precision-engineered 3D models and mechanical designs, showcasing expertise in various CAD platforms and engineering principles.

Cylinder Engine

High-performance 4-cylinder engine with detailed internal mechanisms and fluid dynamics simulation. Features precise timing and valve operations.

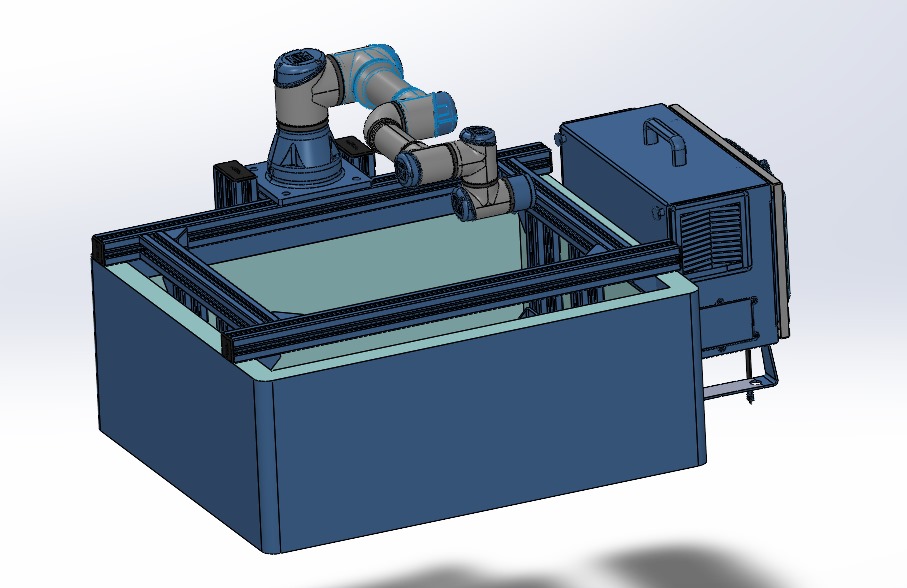

Travel System with Robotic Arm Assembly

Mobile scanning system with robotic arm assembly, designed in SolidWorks and Vention for easy dismantling and setup-ideal for on-site inspections during travel

Cylindrical Conveyor System

Designed a cylindrical conveyor using Fusion 360 and SolidWorks to transport cells for precise transducer scanning, enhancing defect detection accuracy in high-throughput inspection

Differential Gearbox

Advanced differential gearbox design with complete motion study, stress analysis, and torque distribution simulation

Featured Projects

COBRA - Crater Observing Bio-inspired Rolling Articulator

Assistive Robotics Research Project

Project Overview

COBRA is a snake-inspired lunar rover designed to explore and analyze challenging lunar craters. This innovative project integrates bio-inspired mobility with advanced perception systems for navigating steep slopes and rough lunar terrains.

My Role

As the 3D Modeling and Object Detection Specialist, I designed and developed critical components using SolidWorks, particularly the redesigned head module. I also implemented and fine-tuned YOLO algorithms for real-time obstacle detection and terrain analysis.

Key Highlights

- Bio-inspired gaits for optimal lunar crater exploration

- Advanced perception module with semantic segmentation

- Modular design with improved battery access

- Custom dataset creation for crater navigation

Technologies Used

Coffee Bean Color Sorter

Undergraduate Final Year Project (2019)

Project Overview

Developed an affordable and precise optical sorter for green coffee beans using image classifiers and a Raspberry Pi 3. This solution provides small-scale coffee farmers with a reliable way to sort beans by quality, enhancing the efficiency and sustainability of coffee production.

My Role

As a member of the design team, I contributed to concept development, component selection, and design integration. I worked on the design of the hopper, conveyor belt, color sensor, and gate actuators, ensuring these components functioned together seamlessly.

Technologies Used

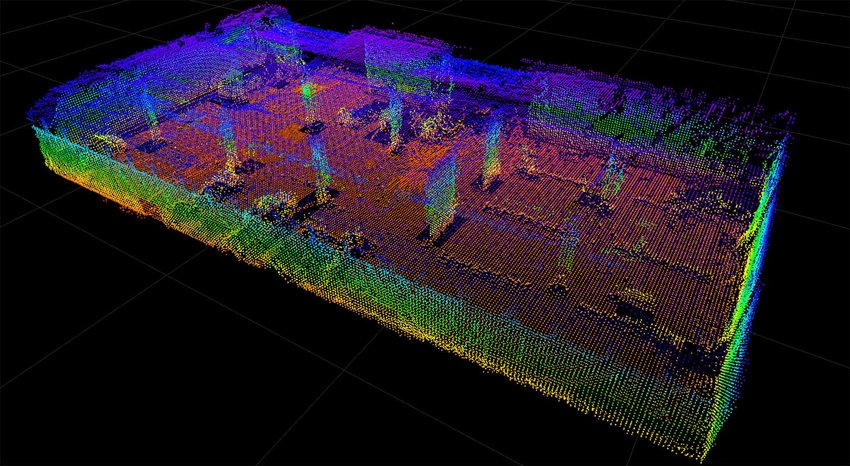

SLAM Algorithms Comparative Analysis

RSN Research Project

Project Overview

Conducted a comparative study on ORB-SLAM (Visual SLAM) and Cartographer (LiDAR SLAM) algorithms to analyze their performance in mapping and localization. The project assessed each algorithm's accuracy, efficiency, and suitability for different environments.

My Role

Led the research effort in comparing visual and LiDAR-based SLAM approaches, conducting experiments and analyzing performance metrics to determine optimal use cases for each technology.

Technologies Used

Skills & Expertise

CAD Design

Robotics & Automation

PLC & Control

Mechanical Design

Get In Touch

Let's Connect!

Feel free to reach out to me on LinkedIn. I'm always open to discussing new opportunities and collaborations.

Message on LinkedIn